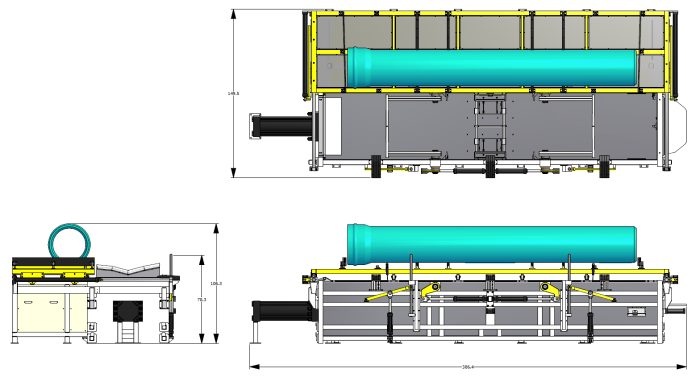

Isometric view of In-line Hydrotester 3D CAD model.

Basic dimensions of machine in inches.

The hydrotester had to be modular in its design, as to be able to ship it using standard shipping containers. This image shows the hydrotester in its packed configuration inside a simulated 40ft container.

This image shows a cross-sectional view of the sequence that a pipe follows as it goes through the machine.

In order to perform the pressure test, the pipe is filled with water such that there is no air trapped inside. Then the ends of the pipe are plugged up. The main structure of the machine must withstand the force that the pressurized pipe will exert on the plugs. This force can be as high as 700,000 lbf for large diameter pipes.

FEA simulations were performed on the main structure to ensure that it would perform well under the large loads described earlier. The machine was designed to have high fatigue resistance.

This is an image of the final machine installed at the PVC pipe factory.

This image shows the main water pumps for the machine.

A water filtration system was necessary for the machine, as the PVC pipe factories tend to be very dirty environments.

The machine motions are achieved through hydraulic actuators, requiring a large hydraulic power unit, shown here.

gLike