Initial concept - A shoe hull made from aluminium rod welded together. It would then be covered with a waterproof skin. This forms a very lightweight but strong hull.

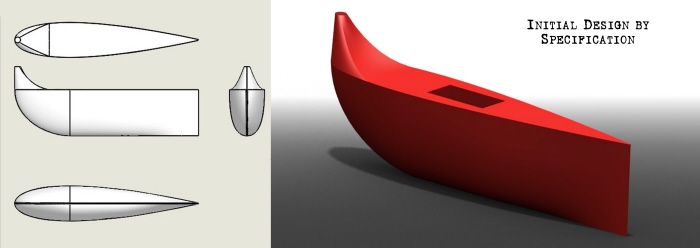

Initial design from specifications - This shoe design was based on specifications drawn up by my group; it was a starting point from which to develop.

CAD model of final design - SolidWorks model I made of our group's final design. This model was used to produce working drawings for manufacture. I calculated NACA aerofoil profiles for the hull and rear fin specific to our design dimensions. This was a 3rd year university project to 'Walk on Water'. The vehicle could only be attached to your feet with no external power source.

Finished product - Final shoes made from high density polystyrene, plywood and sheet aluminium. We won an award for 'Engineering Elegance'.

Test Day - Here I am trying out our shoes on the test day. They worked very well and few changes were needed before our final event.

Walking on Water Test Day - As a shoe moved forwards the fin on the back moved to the horizontal position dew to the force of the water. As a shoe moved back the rear fin moved to the vertical position creating a very high drag coefficient.

gLike