3D Printed Bottle Cap Prototype Designed for Noruell Labs

Painted 3D Printed Bottle Cap Prototype Designed for Noruell Labs

3D CAD Bottle Cap Concept Designed for Noruell Labs

3D CAD Drawings of the Bottle Cap Concept Developed for Noruell Labs

3D CAD Bottle Nail Polish Remover Packaging Concept Designed for Noruell Labs.

3D CAD Drawings of Bottle Nail Polish Remover Packaging Concept Designed for Noruell Labs

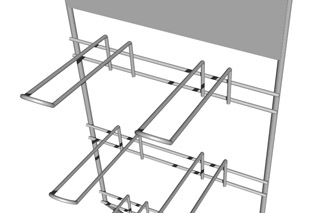

Wire Display Kiwi products - P.O.P, developed with Customade ID.

Wire Display Kiwi products - P.O.P, developed with Customade ID.

Newspapers Stands - Developed with Customade ID for Omnimedia company.

Newspapers Stand - Developed with Customade ID for Clave Digital company

Newspapers Stand production models - Newspapers Stands model design and manufactured for Clave Digital company by Customade ID

Newspapers Stand production models - Newspapers Stands model design and manufactured for Clave Digital company by Customade ID

Wire Shelving - Custom made Shelving for a kitchen

Wire Shelving - Custom made Shelving for a kitchen

Wire Shelving - Custom made Shelving for a kitchen

Wire Shelving - Custom made Shelving for a kitchen

Wire P.O.P - for Customade ID

Wire exhibits - I made the interships in this company, we made a lot of interesting stuff, like, newspaper stands, battery exhibits, and much more.

Cart for Obleas selling - A cart made from Wood and PVC material, printed on the base and top.

Cart for Obleas selling - A cart made from Wood and PVC material, printed on the base and top.

Real model of Obleas cart

Real model of Obleas cart

Early work

Rendering of the Nautica Perfume.

Nautica perfume bottle - Modeled in rhino and rendered in cinema 4d

Del Monte Cup mold Proposal - Cup's mold for Vacuum Thermoforming

Del Monte Cup mold Proposal - Modeled the recent cup for the Vacuum Thermoforming mold

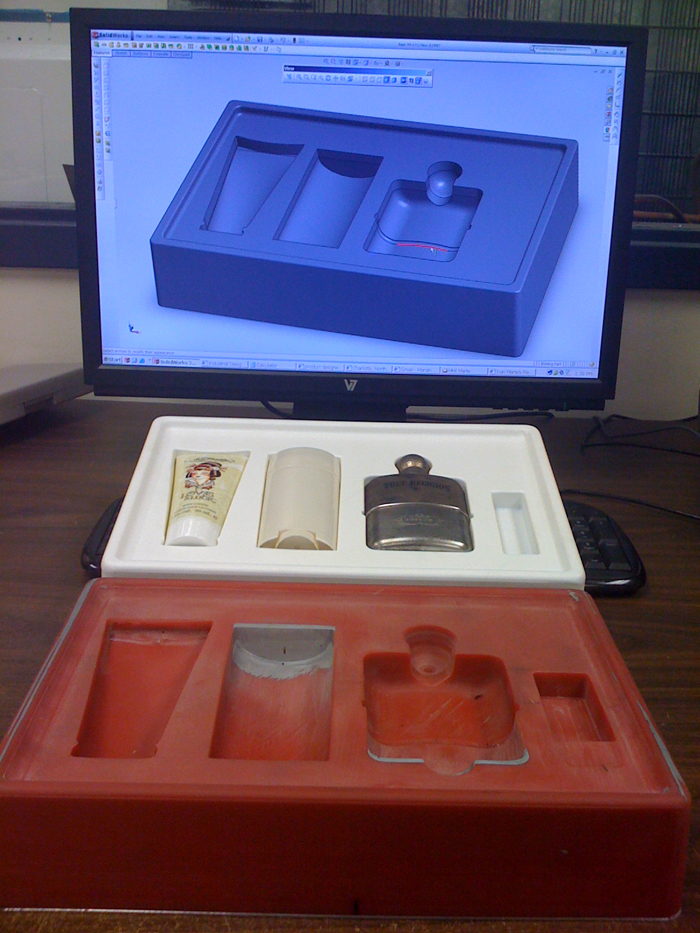

Packaging - A few samples of my current work...

This is the basic process :

1st. Dimensioning the current bottles or cosmetics.

2nd. 3D Modelling of the mold using solidworks.

3rd. Programming the 3d into NC codes. Using Gibbs CAM.

4th. Machining the mold in the CNC, in different kinds of materials for samples, and alluminum for the final mold.

5th. Vacuum forming for real package

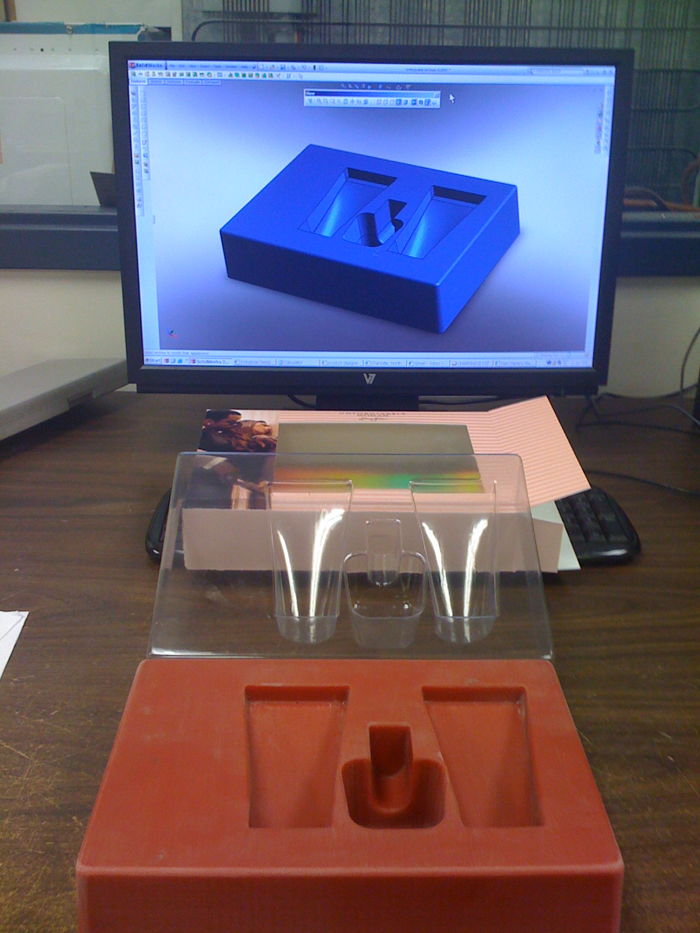

Packaging - A few samples of my current work...

This is the basic process :

1st. Dimensioning the current bottles or cosmetics.

2nd. 3D Modelling of the mold using solidworks.

3rd. Programming the 3d into NC codes. Using Gibbs CAM.

4th. Machining the mold in the CNC, in different kinds of materials for samples, and alluminum for the final mold.

5th. Vacuum forming for real package

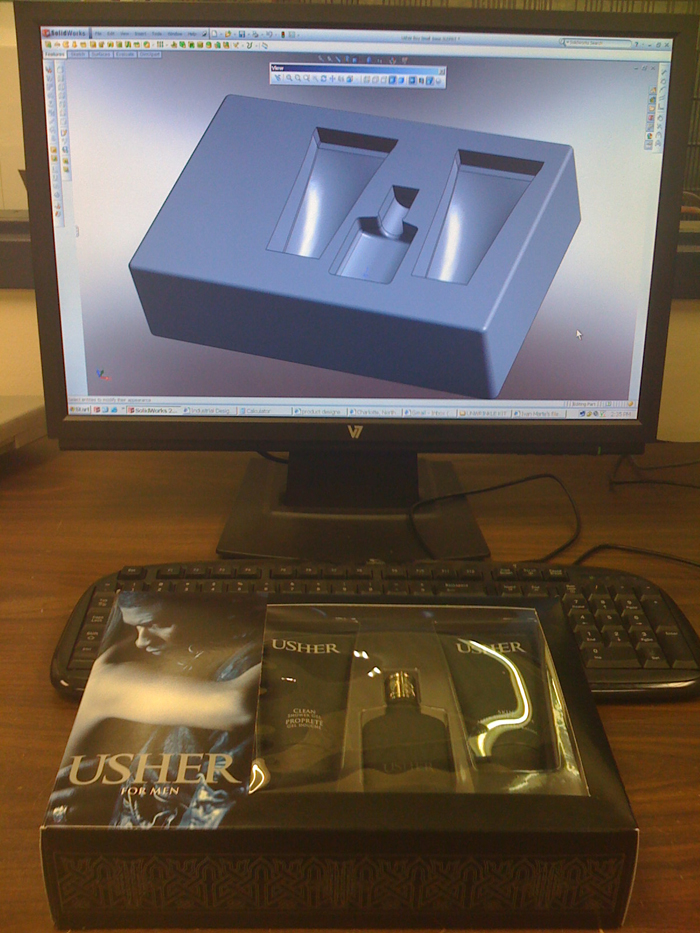

Packaging - A few samples of my current work...

This is the basic process :

1st. Dimensioning the current bottles or cosmetics.

2nd. 3D Modelling of the mold using solidworks.

3rd. Programming the 3d into NC codes. Using Gibbs CAM.

4th. Machining the mold in the CNC, in different kinds of materials for samples, and alluminum for the final mold.

5th. Vacuum forming for real package

Packaging - A few samples of my current work...

This is the basic process :

1st. Dimensioning the current bottles or cosmetics.

2nd. 3D Modelling of the mold using solidworks.

3rd. Programming the 3d into NC codes. Using Gibbs CAM.

4th. Machining the mold in the CNC, in different kinds of materials for samples, and alluminum for the final mold.

5th. Vacuum forming for real package

Packaging - A few samples of my current work...

This is the basic process :

1st. Dimensioning the current bottles or cosmetics.

2nd. 3D Modelling of the mold using solidworks.

3rd. Programming the 3d into NC codes. Using Gibbs CAM.

4th. Machining the mold in the CNC, in different kinds of materials for samples, and alluminum for the final mold.

5th. Vacuum forming for real package

Packaging - A few samples of my current work...

This is the basic process :

1st. Dimensioning the current bottles or cosmetics.

2nd. 3D Modelling of the mold using solidworks.

3rd. Programming the 3d into NC codes. Using Gibbs CAM.

4th. Machining the mold in the CNC, in different kinds of materials for samples, and alluminum for the final mold.

5th. Vacuum forming for real package

Packaging - A few samples of my current work...

This is the basic process :

1st. Dimensioning the current bottles or cosmetics.

2nd. 3D Modelling of the mold using solidworks.

3rd. Programming the 3d into NC codes. Using Gibbs CAM.

4th. Machining the mold in the CNC, in different kinds of materials for samples, and alluminum for the final mold.

5th. Vacuum forming for real package

gLike