A long zig zag channel to mix yellow and blue dyes to make green. They will only mix if their flow is turbulent. If the flow is laminar they flow side by side without mixing.

Standard T-mixer hooked up to pumps.

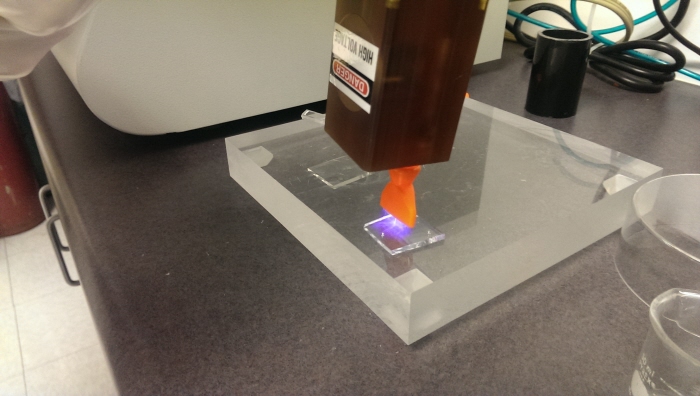

The purple lightning coming out of that orange tip is plasma. Plasma is just ionized gas, in this case Argon, its the same stuff you would find in a purple neon sign. Definitely not as cool as it sounds. The plasma alters the surface chemistry of the PDMS by removing hydroxyl groups, this allows both sides to stick together.

gLike