Metal parts and plastic parts were designed in SolidWorks with details for production tooling.

This foldable metal construction concept made so much sense that no other concept was needed. For quick execution, Rhino was used for design and rendering.

This foldable concept utilizes blow molded parts.

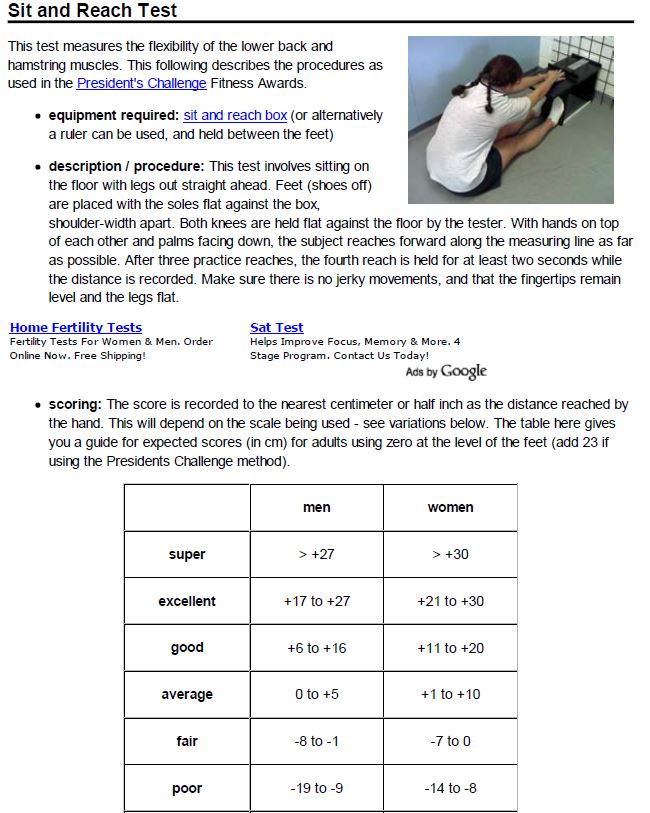

I conducted a research of flexibility test method and procedure to have a full understanding of the requirement and how the product was used. The subsequent design should not interfere with the testing requirement in anyway.

Client's existing product was made of heavy sheet metal. The construction was hard to use and unsafe.

gLike