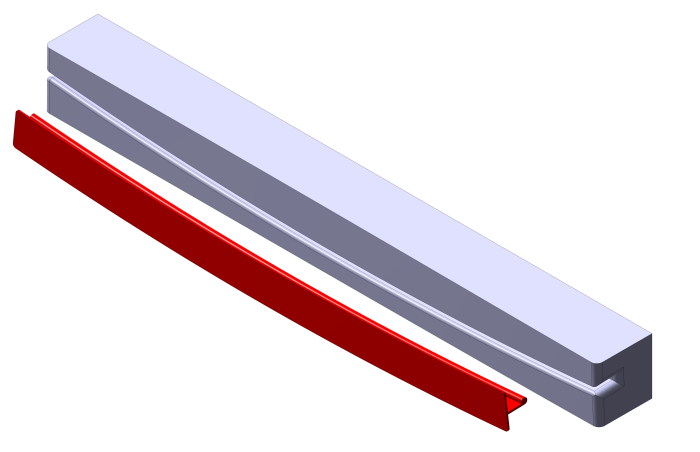

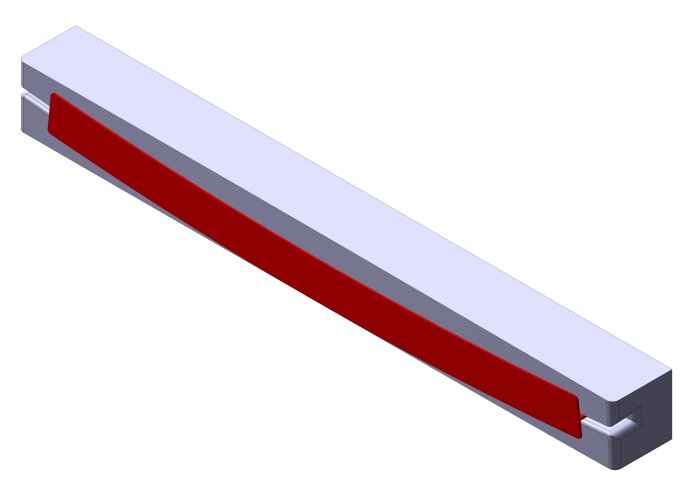

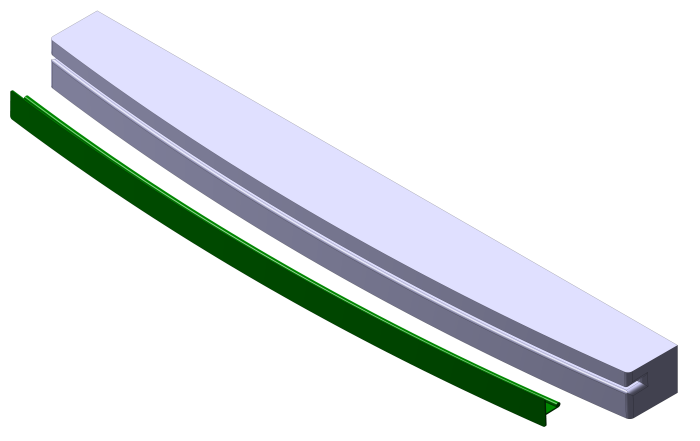

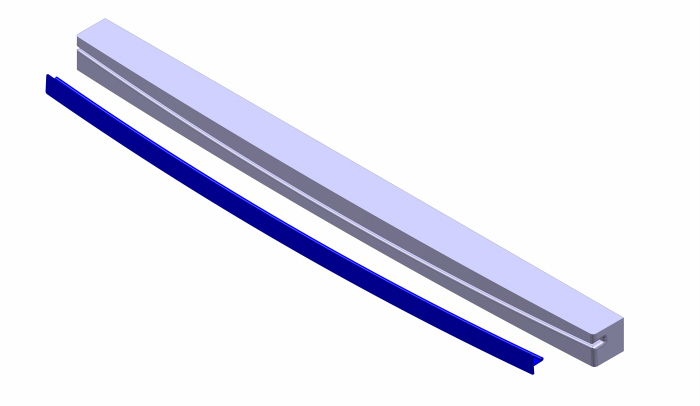

Stringers are represented in red, green, and blue. The corresponding stretch form blocks are shown in gray.

The primary structural components of an airplane fuselage are frames and stringers, which together make up the skeleton of modern commercial aircraft. Frames run perpendicular to the fuselage skin, simultaneously giving the aircraft shape and preventing the skin from buckling under bending loads. Stringers run parallel to the fuselage skin and transfer the aerodynamic loads from the skin to the frames. Stringers provide a significant increase in skin strength with a minimal increase in weight.

In the figure, stringers are represented by number 16 and are colored red, blue, or green.

The stringer (represented in red) is gripped in the arms of the stretch-form (represented in blue) and stretched over the stretch-form block until plastic deformation is achieved.

gLike