Smoothed out foam mold

Another shot of the foam core.

Assembled recumbent bike frame to be used for competition

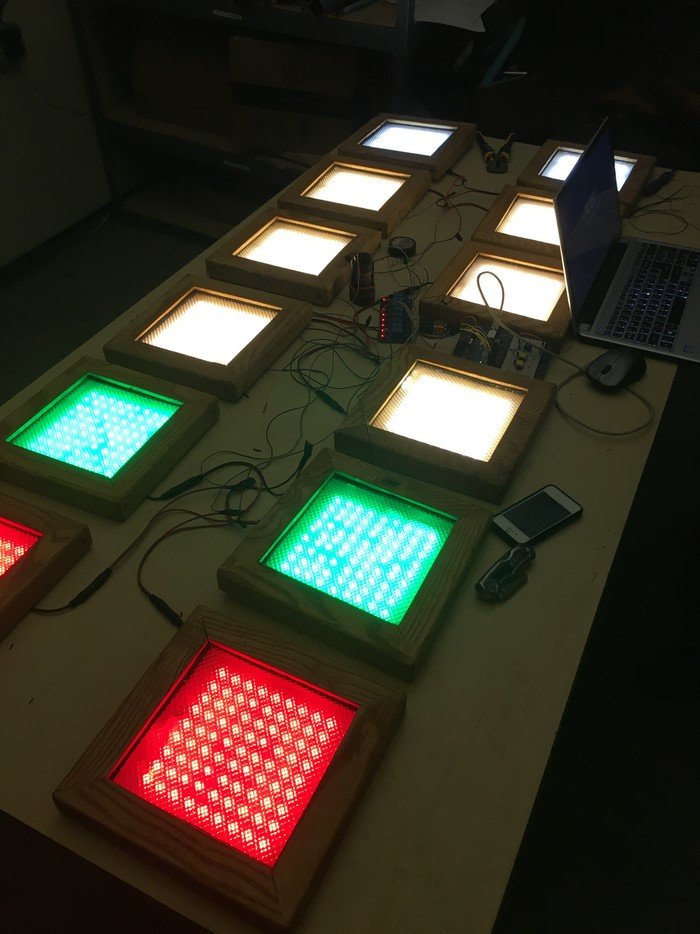

LED light tree to be used for competition. This side-project exposed me to LED's, wiring, and microcontrollers. This picture was taken while the tree was being programmed for the start of a race.

The HPV team's final build pictured at competition. (Photo Credit to Ohio University)

gLike