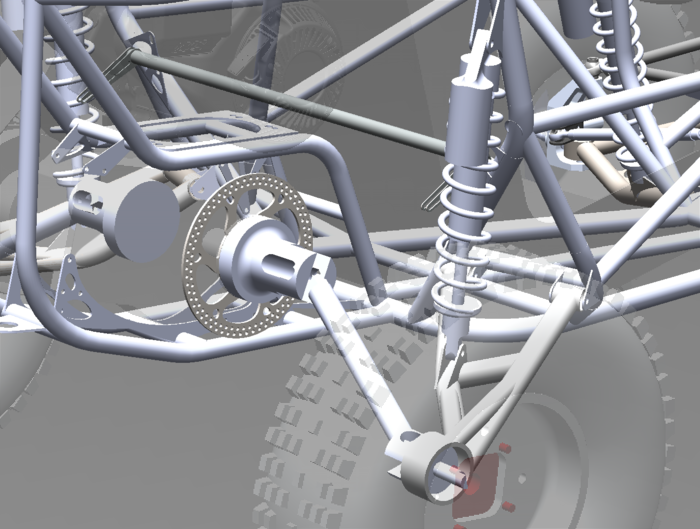

The car assembly, with the non-transparent items being either designed by me completely or with direct involvement.

Above, the steering knuckles/wheel uprights are seen. A welded design was considered, but a CNC design fit the team goals better – saving weight and money. These were made for free by a sponsor, who waterjet the outline and CNCd the rest. In this way, very little machining time was needed, and the design was set up this way intentionally.

The Steering knuckle simulation was performed with a “mock spherical bearing” and a “mock hub” for correct representation. There was no weight constraint, since these knuckles first had to serve the kinematics, and work reliably in the 4h endurance race. They weighed 1.5lb each.

The rear trailing arms were a first for the team, and were done for increased ground clearance and reduced chance on them catching on a rock, like a traditional arm could. This meant extensive FEA, with a crooked landing scenario. Sheet metal designs were tried and abandoned, and the bent tube design worked well and weighed 3.3lb. Heavy, but it ensured it could reliably land on one wheel, in the 4h endurance race.

The frame jigging was performed manually, without any standing fixtures. Due to the abundance of bent tubing, this worked well. Certain helper jigs were set up for suspension tabs and engine

mounting, but one design goal was to allow for most of the jigging to be done with the help of 90deg clamps, and sliding the component into place.

gLike